Installing mobile electronics systems is not as easy as it used to be. In the “good old days,” cars were made from thick metal and didn’t have many electrical components. Modern vehicle construction makes use of the thinnest, lightest materials possible. These body panels are held together with non-conductive adhesives, and it seems that every square inch of our cars and trucks are packed with computers, sensors and modules. Even a task as simple as wiring an amplifier can become quite complex.

Installing mobile electronics systems is not as easy as it used to be. In the “good old days,” cars were made from thick metal and didn’t have many electrical components. Modern vehicle construction makes use of the thinnest, lightest materials possible. These body panels are held together with non-conductive adhesives, and it seems that every square inch of our cars and trucks are packed with computers, sensors and modules. Even a task as simple as wiring an amplifier can become quite complex.

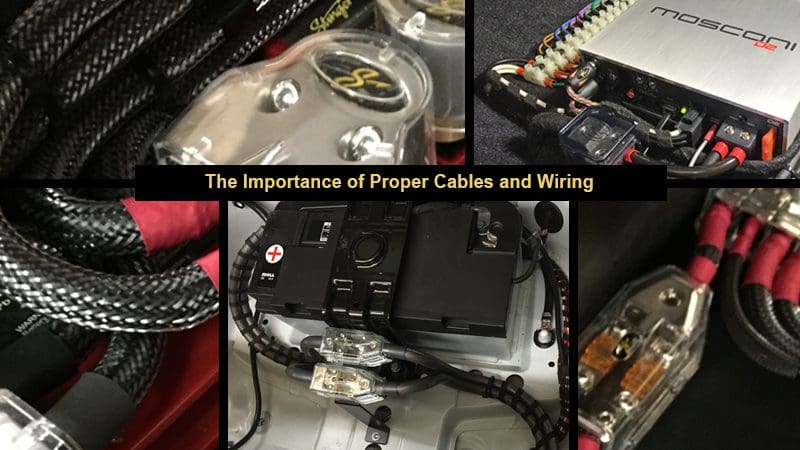

In this Best Car Audio article, we look at the importance of proper wiring techniques and materials, and the effect they have on the performance of an aftermarket audio system upgrade.

Power Delivery

This article is about installing a five-channel amplifier in a vehicle with a factory head unit. There are two important tasks when it comes to installing an amp: getting a signal to it and getting power to it. For an amplifier to produce power, you need to feed it power. The primary source of power in our vehicles is the alternator, followed by the battery. Most people focus on running a large conductor from the positive terminal of the battery to the positive terminal of the amplifier. While this is important, where and how the amplifier is grounded is equally important.

This article is about installing a five-channel amplifier in a vehicle with a factory head unit. There are two important tasks when it comes to installing an amp: getting a signal to it and getting power to it. For an amplifier to produce power, you need to feed it power. The primary source of power in our vehicles is the alternator, followed by the battery. Most people focus on running a large conductor from the positive terminal of the battery to the positive terminal of the amplifier. While this is important, where and how the amplifier is grounded is equally important.

Quality installers will know the best locations on a vehicle to make a ground connection. They will know how to handle a vehicle with an aluminum or composite chassis. They will know how to recognize vehicles that are assembled with adhesives instead of spot welds. If you are installing a large amplifier, they will know how to upgrade the factory wiring under the hood to handle the extra current draw.

Protecting your vehicle is a part of installing power wire. In the unlikely event you get into an accident or something bad happens to your amplifier, the wiring and the equipment installed in your vehicle need protection in the form of a fuse. A good installer will install a fuse as close as possible to each source of power for the system. In most installations, this is near the main battery.

Some systems have secondary batteries and require additional fuses for proper protection. If you have the choice, a fuse provides better protection device than a circuit breaker. Fuses offer more surface area for power conduction. Also, there is absolutely no chance that a properly installed fuse could fail in a condition that may allow current to continue to pass.

Signal Integration

The audio systems in modern vehicles are becoming increasingly complex. Manufacturers (JBL, Infinity and Lexicon) are turning to suppliers like Bose and Harman for increasingly complex audio systems. Each of these companies employs highly trained engineers who spend months tuning each new system.

Trying to source an audio signal that will work with aftermarket equipment is becoming increasingly difficult at the same time. A properly trained installer will have the knowledge and experience to measure the signals in the factory system to determine if they can be used as is. If the signals are not acceptable in level, frequency response or bandwidth, your installer can recommend the correct component to correct them.

Your installer will also know to test each signal source across multiple functions. Ensuring that factory Bluetooth, navigation prompts and parking sensor warnings continue to work as intended is important to you being able to enjoy your upgraded audio system.

Noise Prevention

Dealing with factory computers, sensors, data networks and other high-current components can cause interference with the delicate low-level audio signals we send to our amplifiers. If you are not using good-quality interconnects that offer a twisted-pair design and appropriate shielding, you leave yourself open to picking up all sorts of strange noises. Likewise, choosing the right equipment is critical. You want to ensure that each component in the signal path has differential inputs to reject any noise that might be imposed on your interconnects, or the speaker wires running to the input of your amplifier.

The amplified signal coming from your amp is still subject to noise. Passive crossover networks can be notorious for picking up electromagnetic noise. Where your installer places the passive networks is quite important. An experienced installer knows what to avoid for your system to sound great and be noise-free.

Choice of Wiring Materials

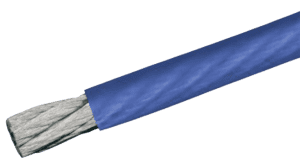

There are two options for power and speaker wire – CCA and what most refer to as OFC. CCA stands for Copper Clad Aluminum. CCA typically is an inexpensive wire that is part aluminum and part copper. Aluminum costs less than copper, but it also does not conduct as well. You will usually see CCA wiring labeled with Gauge or GA when referencing its size. It is also worth noting that, unless the wiring you have chosen says AWG on it, there is no standard for the size of the conductor within the jacket.

Combine that with not knowing the ratio of copper to aluminum, and you run the risk of starving your amplifier for power. We have seen CCA 4 gauge wires that present almost four times the resistance as a proper 4 AWG conductor.

OFC stands for Oxygen-Free Copper. The term OFC has become the accepted slang term for all copper wiring. Properly sized copper wiring (using the AWG standard) offers the best possible power delivery to your amplifier.

Working on modern vehicles has its challenges, but those challenges come with rewards regarding background noise levels, convenience and features. Trust the installation of your audio equipment to qualified professionals. They have the experience to get the job done right the first time. Visit your local mobile electronics retailer to find out more.

This article is written and produced by the team at www.BestCarAudio.com. Reproduction or use of any kind is prohibited without the express written permission of 1sixty8 media.